YAG laser is a solid laser based on a yttrium aluminum garnet. The chemical formula of yttrium aluminum garnet is Y3Al5O15. Similar to various other solid lasers, the basic parts of the YAG laser are the laser functioning product and also the pump resource unified vibration cavity.

However due to the activation of doping ions in the crystal, different kinds of pump resources are utilized, as well as the pump, in a different way taken on by the tooth cavity structure, is different. The various other functional frameworks of the gadget, the YAG laser, can be separated into a variety of, for instance. According to the result waveform. It can be divided right into continuous wave frequency YAG laser, YAG laser, and also pulse laser, and so on.

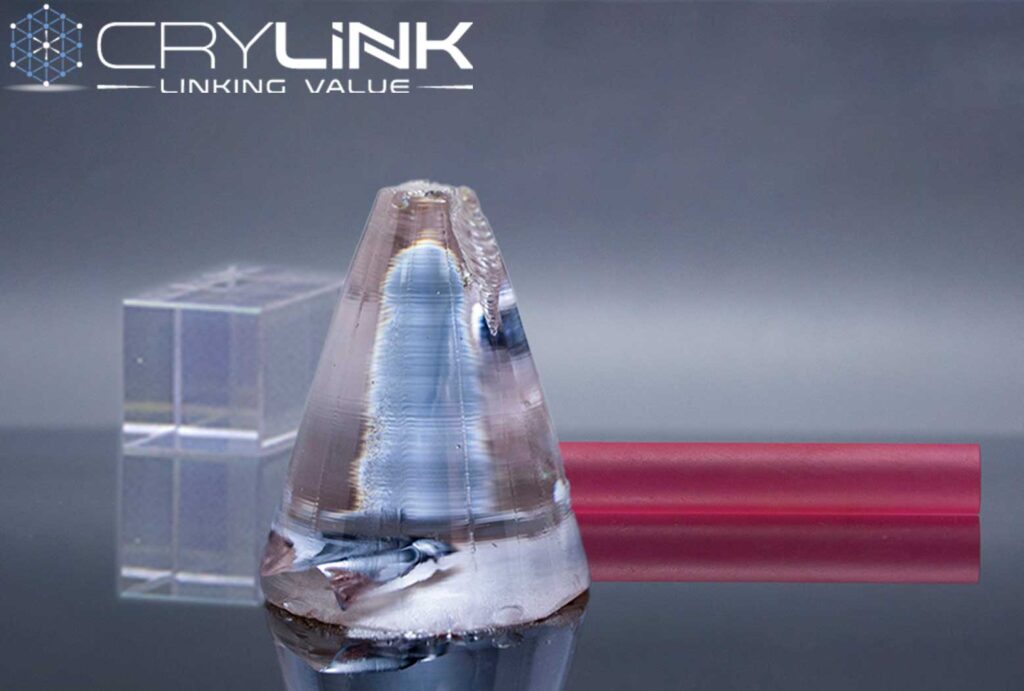

According to the functioning wavelength. It can be separated into 1.06 μmYAG laser and frequency-doubled YAG laser. Raman frequency change YAG laser as well as tunable YAG laser, etc. Various doping can be split into Nd: YAG laser, doped Ho, Tm, Er, and more YAG laser; According to the crystal form, it can be separated into a bar and strip YAG laser. The various outcome power can be divided into high power and also tiny power YAG laser.

Er: YAG laser crystal

Er: YAG crystal comes from the cubic crystal system, an appealing solid laser product in the mid-infrared band. Which can outcome a laser of 3 wavelengths at area temperatures: 1.64 μm, 1.78 μm, and 2.94 μm. Amongst which 1.64 μm and 1.78 μm are in the safe band of human eyes, 2.94 μm remains in the hydroxyl absorption peak and can be strongly absorbed by biological tissues, so it has an excellent application possibility in laser medication, laser interaction, laser distance dimension, and so on.

Nd: YAG crystal

Nd: YAG is one of the laser crystals with exceptional detailed performance and important applications. Because of its exceptional basic residential or commercial properties. It is commonly utilized in commercial, clinical, military, and also clinical research study areas.

Nd: YAG crystal Features:

- High optical quality, low loss

- High gain, low limit, high performance

- Appropriate for high typical power solid state laser

- High mechanical stamina, superb thermal conductivity as well as thermal shock resistance

- Appropriate for all laser working settings (continuous, pulse, Q switch, setting securing, regularity increasing, etc).

Tm: YAG laser Crystal.

Tm: YAG crystal, thulium-doped yttrium aluminum garnet crystal. The self-quenching mechanism of H4 and also F4 degrees of Tm: YAG crystals can generate two-photon excitation at the top level, possibly providing an efficient method for the laser to acquire high quantum performance.

Tm: YAG crystals are widely utilized in LiDAR and various other atmospheric discovery fields due to their operating wavelength of 2013nm.

Complying features:

- The fluorescence lifetime of a Tm is 9.2ms@6 %.

- A Tm: YAG crystal is two times as long as a Tm: YAP crystal.

- Tm: YAG crystals produce a slightly lower cross-sectional location than Tm: YAP crystals.

- The optimal absorption band is 785nm.

- More suitable for the pump of the semiconductor diode.

YAG laser light beam top quality is good and has the advantages of high efficiency, affordable, security, security, precision, and also high integrity. A straight slot is tiny in details applications, utilizing YAG laser devices and also handling speed, high effectiveness, and much better financial benefit. The cut surface area is smooth as well as can get a larger depth-to-diameter proportion, as well as the warmth deformation, is deep and large, and can be hard, breakable, as well as soft on various products such as processing. There is no device wear or replacement. No mechanical becomes simple to automate. High processing pump effectiveness can be achieved under special conditions, approximately about 20%. With the effectiveness improvement, the laser tool’s warm tons lower. For this reason, it considerably enhances the top quality of the beam’s lengthy life, high reliability, small dimension, light-weight, as well as appropriate for miniaturization applications.

Application

YAG laser is suitable for laser cutting, welding, and also boring of steel products: such as carbon steel, stainless steel, alloy steel, aluminum and alloy, copper and alloy, titanium as well as alloy, nickel-molybdenum alloy, and other materials. Widely utilized in air travel, aerospace, weapons, ships, petrochemical, medical, instrumentation, microelectronics, automotive, and various other markets, it improves processing top quality as well as working efficiency. On top of that, the YAG laser can likewise supply a specific and fast research study approach for scientific research.

Compared with other lasers, the YAG laser can operate in 2 means: pulse and continuous. Its pulse outcome can be obtained by Q-switching and also mod-locking technology to make sure. Its handling variety is larger than that of a carbon dioxide laser. The result wavelength of the YAG laser is 1.06. This is just one order of size smaller sized than the wavelength of the carbon dioxide laser 10.06 um. So it has a high combining performance with metal and great processing performance. One of the most essential is that the YAG laser can be combined with fiber. With the help of time and also the power department, a multiplexing system can conveniently transfer a laser beam of light to multiple terminals or long-distance stations, which is convenient for laser handling to attain adaptability.